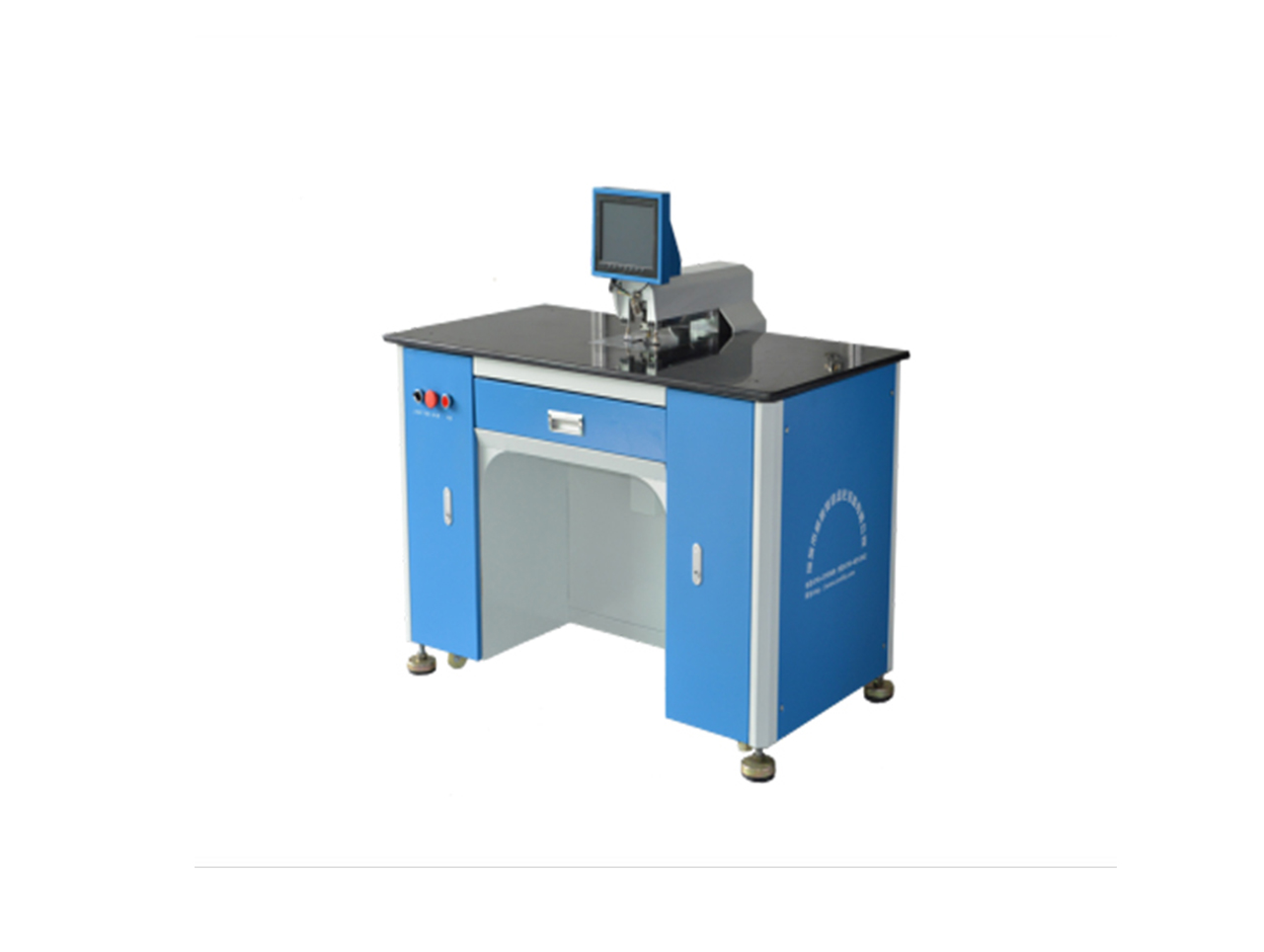

Film automatic punching machine is suitable for: positioning hole processing in electronics, signage, packaging, printing and other industries , PE, PC, PVC film, polyester film, thin aluminum and other boards automatically punch positioning holes

Features of automatic film punching machine:

1. The marble panel is used, which is wear-resistant, practical, beautiful in appearance, generous, reasonable in structure, easy in operation and high in punching accuracy.

2, using windows2000 operating system, the operation is simple and convenient.

3. The original image algorithm has the function of predicting the center and correcting the deviation for the incomplete target type, and the processing accuracy is less than 0.008mm.

4. Full-screen automatic tracking technology, when the target appears, it automatically locks and punches holes, and the whole process only takes 0.4 seconds.

5. Using single chip technology to process, automatically identify the target, and the performance is more stable. It has a variety of light source selection functions to make the image clearer.

6. The optional function of reflected light and transmitted light is adopted, which greatly improves the punching accuracy; 15 color liquid crystal display is beneficial to operation and long-term work.

7. The working mechanism adopts the combination of mechanical and pneumatic, with stable performance and greatly improved punching force.

8. Applicable to various flexible circuit boards, membrane switches, films, nameplates and other materials.

Technical parameters of film automatic punching machine:

Punching diameter: ¢0.5mm~¢4 mm (depending on the user)

1. Identification diameter: ¢0.5mm~¢4mm

2. Machinable materials: various flexible circuit boards, membrane switches, films, sign panels, etc.

3. Maximum processing board surface: 500*600mm

4. Maximum impulse: 100kg

5. A variety of light sources: white ultra-bright LED transmitted light and reflective light

6. Positioning error: <0.008mm<>

7. Punching speed: 0.4 seconds/hole

8. Power consumption: 200W (AC200V~240V single-phase)

9. Air pressure: 0.5~0.8Mpa

10. Weight: 220kg

Advantages of film automatic punching machine:

☆High accuracy: The camera automatically finds the picture within the recognition range, and the computer analyzes and controls the movement.

☆Fast speed: The camera has a short response time, and once the graphics are found, the punching position of the graphics can be controlled.

☆Powerful function: The sample map can be saved and called directly for reuse. Computer system, software can be upgraded in real time.

☆Quality Guarantee: The main components such as pressure regulating valve, cylinder, solenoid valve, track and so on are imported to ensure the service life.

☆Simple operation: man-machine interface, set the working mode directly on the touch screen.

☆High recognition degree: The special light source can automatically identify the positioning hole pattern of materials with high reflection and high blackness, and can automatically fill in the incomplete pattern.

Applicable industries

Specializing in punching of roll material positioning holes for various printing industries. Such as: FPC/flexible circuit board industry, membrane switch, nameplate sign, control panel, film/black/brown sheet, PET/PVC/PC/PP/PE, rolled stainless steel, aluminum plate, self-adhesive label, etc. Roll material.

Features

1. Unique equipment structure, double punch, can punch 2 holes at a time, double the efficiency.

2. Simple operation, CCD automatic positioning + secondary compensation, to ensure that the product is always in the processing area, and the material does not move or shift during the punching process, effectively ensuring the punching accuracy.

3. High punching accuracy! It adopts industrial computer control, CCD camera positioning, imported precision screw guide rail transmission, equipped with precision punching, and imported air cylinder controls punching. Ensure punching error: ≤±0.015mm.

4. The original image algorithm has the function of predicting the center of the incomplete target type, correcting the deviation, and printing the incomplete graphics can identify the punching hole.

5. The working mechanism adopts the combination of mechanical and pneumatic, the performance is stable, and the punching force is greatly improved.

6. Put the product to be punched within the visible range of the CCD, the punching machine will automatically capture the punching pattern, and automatically move and align to complete the punching. The whole process only takes 0.45 seconds. Directly specify the hole type to be punched on the touch screen to set the working mode, and the operation is simple and easy to use;

7. Special alloy steel punching die, durable; high-speed imported high-speed steel punching needle, smooth punch

8. Chinese operation interface, computer with touch screen, touch operation, practical and convenient.

9. The unique three-color light identifies the light source, which can effectively ensure that difficult-to-identify colors (such as white, silver, and other difficult-to-identify colors) can also be easily identified.

10. It can realize fully automatic unilateral or multilateral one-time punching, and the punching machine head can move back and forth.

11. The combination method is simple and convenient, and enterprises can install automatic feeding and feeding systems, automatic laminating machines and automatic cutting machines according to their own needs.

12. Flexible collocation, it can be used with other automatic equipment, such as automatic roll-to-roll screen printing machine, automatic feeding and feeding mechanism, automatic slicer; at the same time, it can also be used for sheet materials.

You are here:

You are here: