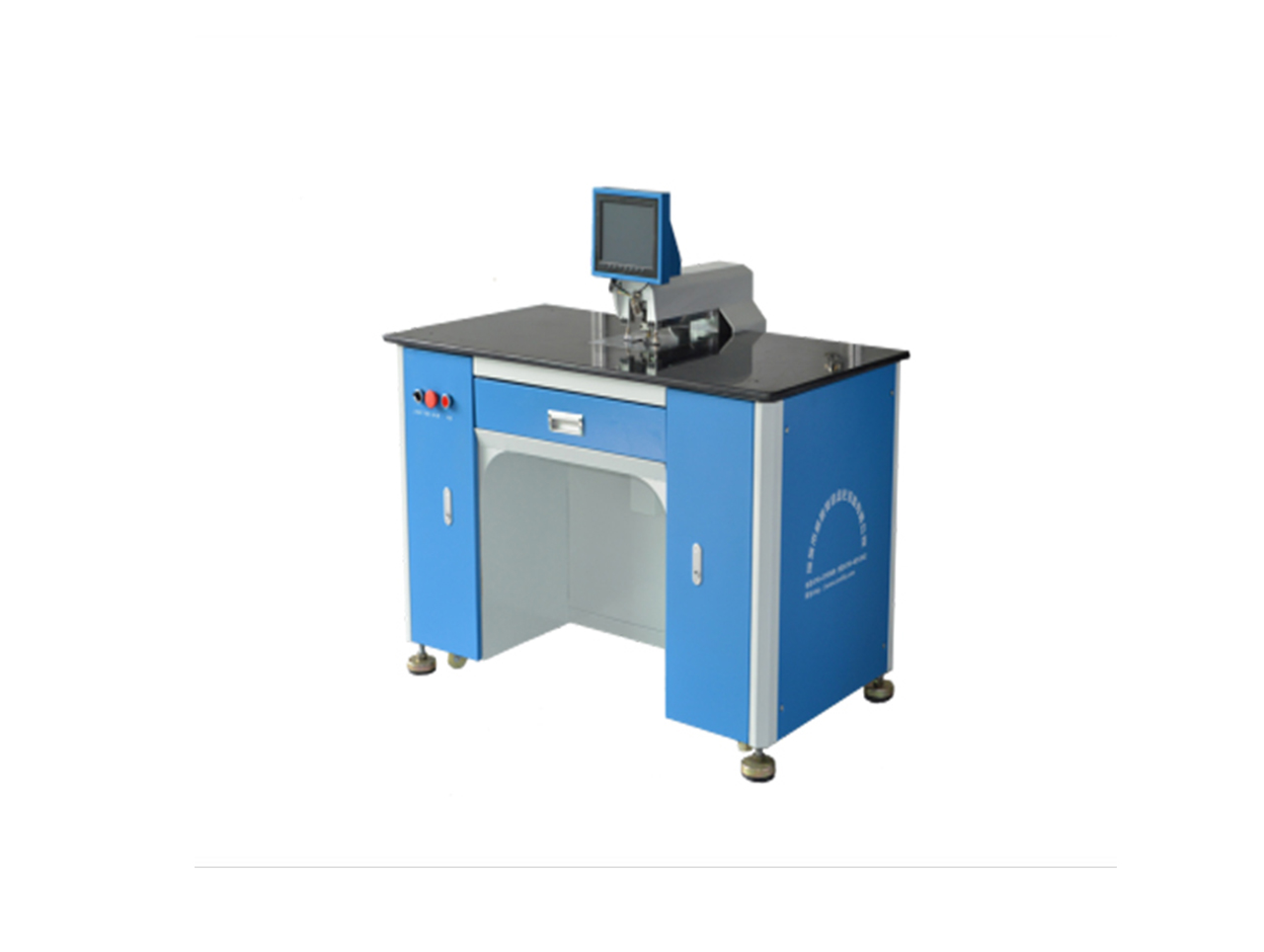

Punching machinery is a major product in the punching industry. It provides the industry with the necessary technical equipment to complete the required product punching process. Punching equipment includes machinery and equipment for the manufacture of synthetic punching materials and container forming. It is a machine that converts raw materials into punching containers after processing and forming. Most of this type of equipment is a complete production line, which is closely related to the process and raw materials.

The quality of the technique is simple and the drilling accuracy is fast, which can save manpower and material resources for the majority of industry manufacturers and further improve the production quality.

* Simple operation, automatic CCD camera scanning and positioning, automatic punching

* The punching speed is fast. Compared with traditional manual drilling, the average punching speed of this equipment is 0.4 seconds/hole, which is more than 10% of the traditional manual punching speed.

* High targeting accuracy, the overall error is less than or equal to 0.015mm, and the highest accuracy can reach 0.008mm

* The punching effect is good, the edge of the punched hole has no cloak and no burr, and the punching position is smooth.

* Stable performance, reliable performance and quality guaranteed.

* The mold is hardened high-speed steel, durable

* The system interface is user-friendly, easy to learn, Chinese and English interface can be changed, and there is a touch screen for touch operation.

* It can also identify incomplete and incomplete holes, and automatically punch holes

You are here:

You are here: