Punching machinery can be divided into automatic punching machinery and semi-automatic punching machinery according to the punching size and the supply method of punching materials; if divided according to the use range of punching size, it can be divided into general punching machine, dual-purpose punching machine According to the punching material, it can be divided into a light punching machine, a heavy punching machine and a multi-station punching machine. For processing various materials, such as PCB circuit board, FPC soft board, IMD/IML, film, diazo sheet, mobile phone panel, mobile phone button, self-adhesive, membrane switch, film, PE, PC, PVC, PET film, Polyester film, thin aluminum, aluminum substrate, FR4 glass fiber board, stainless steel and many other materials.

In addition: if the material for the customer's punching is relatively special, our company can also customize it for them, and finally achieve the effect of customer satisfaction

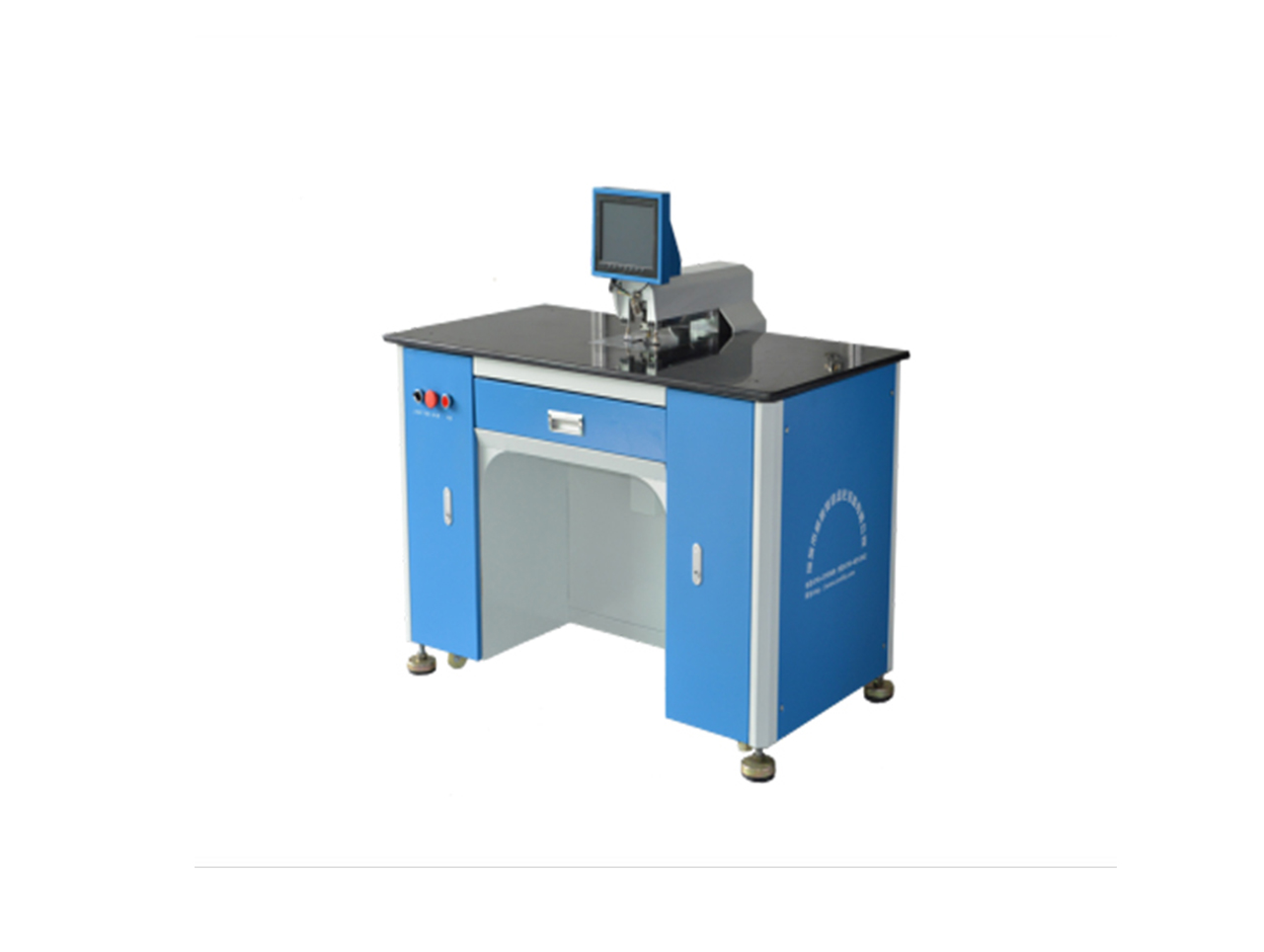

technical parameter:

a, Machining accuracy: <0.015mm b, Machining speed: 0.5 sec Hole c, Punching force: 1200n d, Machining thickness: 0.01mm~3mm (depending on the material) Punching e, Diameter: 1mm~5mm (standard, mold Can be customized) f, air pressure requirements: 0.4~0..8mpa g, power requirements: ac220v~50hz h, light source: infrared transmission, infrared reflection equipment i, weight: 200kg±5kg i. Dimensions: 1250*770*770

Punching machinery is a major product in the punching industry. It provides the industry with the necessary technical equipment to complete the required product punching process. Punching equipment includes machinery and equipment for the manufacture of synthetic punching materials and container forming. It is a machine that converts raw materials into punching containers after processing and forming. Most of this type of equipment is a complete production line, which is closely related to the process and raw materials.

The operation quality is simple and the punching accuracy is fast, which can greatly save manpower and material resources for manufacturers in the industry, and further improve the production quality.

You are here:

You are here: